Farmaceutici Formenti – Gruenthal, a company specialised in effective pain-relieving treatments and cutting-edge pharmaceutical technologies worldwide, was looking for a labeling system suitable for two types of injection pens containing special drugs to treat chronic inflammatory diseases.

The aim was to “improve the productivity of an existing process while increasing of the product potentials and quality” declares Sergio Rollini – Process Equipment Maintenance Senior Manager Engineering at Formenti – an orientation that expresses the company’s continuous desire to “meet the needs of customers with a spirit aimed at possible future demands, new markets, and new technologies”.

To obtain the result, Etipack focused in particular on the study of the correct type of transport necessary for product handling, working on strong customisation to facilitate labeling. The key elements to consider were in particular: the format variation management – cylindrical and quadrangular section – and the existence of a window on the side surface of the pens, which required precision in label application.

The solution: a wrap-around labeling system with custom-tailored shaped roller conveyors

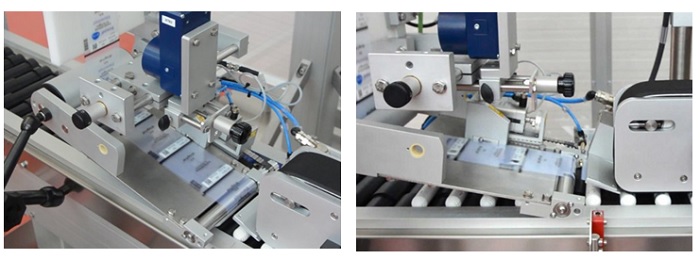

In order to obtain the correct positioning of the pens, it has been developed a customised system for labeling of horizontally-handled cylindrical products with a specific roller conveyor structure. It allows perfect wrap-around label application thanks to cylinders with a specially designed-shape and a support tripod.

The distinctive features of the system include a roller conveyor with specially shaped cylinders to ensure correct positioning during labeling, a special friction rewinder and ultrasound sensor to handle transparent plastic-coated labels, and a non-compliant product rejection system. The machine is provided with overprinting control, a PLC Single operator interface to manage all the operational functions with specific features for the pharma sector: CFR21 management for users and formula variables with audit trail on EXPRESS2008 SQL database; batch management with queries and reports; disaster recovery; back-up restore.

Special-designed anti-filming device for label rejection before application: zero errors, zero losses

Products labeled with the customised System, besides having a particular conformation, also have a high cost due to the pharmaceutical preparation contained within them. In order to avoid product waste and therefore reworking, as well as to reduce machine downtime, Etipack designed and installed a special solution able to avoid the application of the label in case of errors and non-conformities detection.

The anti-filming device prevents the label to be discarded, from being applied by ensuring that it remains attached to the liner. It is thus ejected, allowing the non-labeled product to be collected in the recovery drawer for re-production. The liner can be easily disposed of together with the discarded labels when replacing the roll.

The solution, therefore, offers considerable advantages: it avoids subsequent rework to remove incorrect labels, reduces machine downtime, saves time, workforce, and above all product value.

The results: an efficient automatic labeling system that has met the demands of Farmaceutici Formenti

The aspects that have been most appreciated by the company are “the compactness with respect to the output and the fact that extra devices of our choice have been integrated, without restrictions, which bring advantages in terms of knowledge and optimisation. The simplicity in the use of the system”– SR. In addition to technical satisfaction, the company also expressed positive opinions about its experience with Etipack and the relationship that has been generated: “An excellent relationship and direct internal contacts within Etipack have paved the way. Then the collaborative spirit, flexibility, value for money and also the proximity to our headquarters led to selecting Etipack as a partner for different solutions and applications”. In particular it was appreciated the presence of “an open and collaborative relationship and the willingness to meet sometimes challenging demands in terms of time and solutions to be adopted,” SR.

Discover Etipack Pharma Systems for labelling, serialisation, track & trace and anti-counterfeit. >> https://etipack.it/en/labelling-machines/pharmaceutical-labelling-machines/