Developing and delivering an innovative modular solution for biopharmaceutical manufacturing requires knowing both the cleanroom technology and the process design of these facilities. Therefore, a functional and innovative new modular concept can be developed only by a multidisciplinary team of experts. The experts must collect the lessons learned in previous modular projects and take into consideration the feedbacks of clients. This was Exyte’s approach when we started the ExyCell development in 2018, and it is still the basis for the current product developments: robotics for human-less operations, digitalisation, digital twins, plug and produce solutions embedded into the ExyCell modules are in the works right now, always trying to stay connected with the real world of our clients, with their medicines at the core of our project.

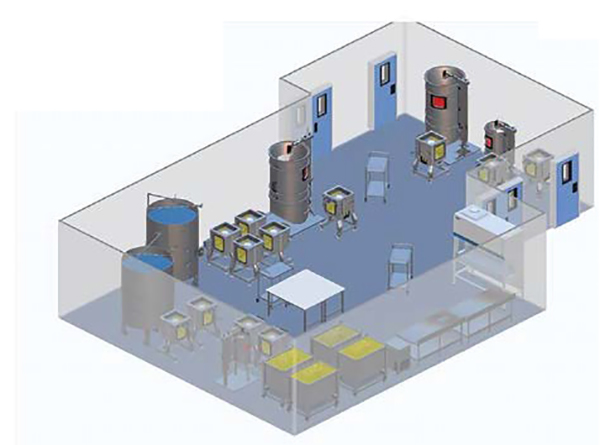

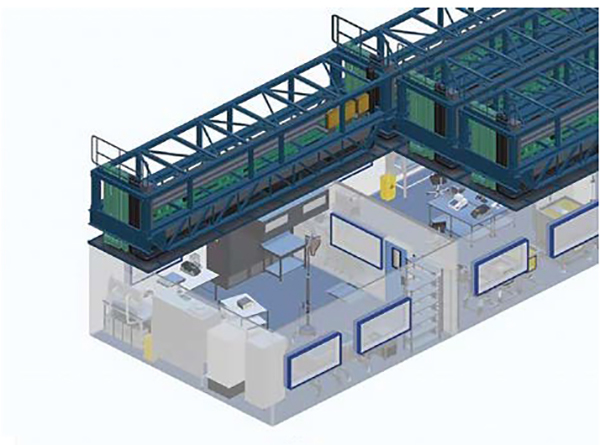

The ExyCell is a ceiling modular skid, 9.6m x 2.4m, available in 7 versions and unlimited combinations of accessories, that can be combined to realise a turn-key biopharmaceutical manufacturing facility up to ISO 5 (according to ISO 14644-1) and Bio Safety Level BSL-2.

To achieve this simple, innovative modular solution, our architects and engineers worked together with construction, logistics, supply chain experts and clients. But the real sweet spot was reached with an “industrial consortium” approach, combining the resources and know-how of Exyte and OEM companies, process owners and technology providers. Since the beginning we invited to the ExyCell initiative a number of highly innovative partners such as Miltenyi Biotec, Siemens, Steris, Syntegon, OUAT! and Univercells Technologies. Their exceptional contributions to the ExyCell ecosystem greatly accelerated and improved our new modular product.

We can now offer standardised yet customisable and scalable GMP facilities for cell and gene therapies, vaccines, mAbs, mRNA, biologics and new medicine modalities, shortening dramatically the design and construction phases.

When it comes to a modular facility producing medicines for human use there is no shortcut: compliance with the cGMP is a must, exactly as a traditional stick-built one. We took this commitment very seriously and the ExyCell is designed to be safely cGMP compliant with the all the main national and supra-national health regulatory guidelines. It is based on proven HVAC and clean utility solutions, with appropriate cleanroom finishes and GAMP-compliant building and process automation systems. Indeed, once finished it looks exactly like any other conventional pharmaceutical facility – or better!

However, during our recent exchanges with the regulatory authorities, we noticed that they are very interested to support proactively both the reliability of the drugs supply and the fast introduction of the new therapeutic modalities. In this perspective we usually establish a productive dialogue with the medical regulatory authority during the design phases, considering holistically the production premises, the support systems and the production processes. All this must cope with the accelerated approval and shorter life cycle of the new generation of medicines. This “fast-track” approach to new medicines development is reflected in several publications by the FDA , EMA and others.

As a further example, the next revision of guidelines such as the EU GMP Annex 1 for the Manufacture of Sterile Medicinal Products offers plenty of room for innovative, prefabricated modular facilities.

If we look at the business drivers, a modular biotech facility is the best option to achieve the shortest time-to-market, thanks to the parallel off-site prefabrication of cleanrooms and process equipment and onsite construction of the building and utilities. We should not forget that being first-or secondto-market with a new mAb, cell therapy or vaccine is critical to secure the expected return on the investment. According to a McKinsey research, first entrants obtain in average a higher market share even after ten years from the launch of a new medicine, with fast-followers however doing still well . Going for a modular, pre-engineered and standardised facility based on the ExyCell system can help to hit the market faster.

Another strong driver today is the pandemic preparedness or fast pandemic response, with governments and institutions financing the realisation of manufacturing plants to secure a local, independent sourcing of vaccines and drugs.

We see these trends converging to generate a strong interest in our modular solutions. A recent example is a new Pandemic Preparedness facility launched in Germany, where the client selected Exyte as general contractor together with our ExyCell modular cleanrooms, in order to meet their ambitious schedule.

The box-in-box approach has been developed over the past decade by the pharmaceutical community to rationalise the design of manufacturing plants and reduce the investment costs and completion time. One of its most successful applications is a modular cleanroom system enclosed in a light, cost-effective prefabricated building. The two “boxes” are built in parallel whereas a traditional stick-built facility has all the works executed in sequence. We saw that the schedule can be reduced from 30 per cent up to 50 per cent, as in our Shanghai Cell Factory realised for Miltenyi Biotec.

Moreover, the inner “box” with the production cleanrooms can be installed in an existing building, accelerating further the schedule.

This simple concept allows also effective function-based value engineering, since the function of the external “box” is limited to providing shelter from the elements and supporting the plant utilities. Following this concept, a light pre-fabricated building can be realised very quickly at a cost comparable to a warehouse: either in Europe or Singapore we can build a single-storey, pre-engineered, prefabricated outer “box” in few months’ time at around 800-1,000 euro/m², depending on the area and level of finishes.

The flexibility of the layout and the speed of execution are additional benefits of the box-in-box modular construction. A truss-beam building can provide long spans without columns, thus allowing plenty of unhindered space for the process equipment.

But the biggest evolution for the modular delivery is linked to standardisation and repeatability: our vision is to have simple, standard building blocks that can be assembled to create standardised yet customisable processing units, which can be combined to realise large bioprocessing facilities. And with our standardised building blocks we eliminate the special transports and complex logistics of the traditional large room modules: a regular truck can transport two ExyCells, occupying less than the space of a 40 ft. container.

Leveraging the concept of pre-defined building blocks Exyte launches at the Interphex in New York a new web-based 3-D layout configurator based on the HakoBio tool by OUAT!. This new tool enables anyone – end-users, production managers, investors, engineers, consultants – to build their biotech facility from scratch. It features a database of some 1,000 pieces of process and support equipment and a library of pre-designed functional areas that can be deployed in a 3D environment with simple drag-and-drop techniques. From the facility conceptual layout we can move quickly to the detailed design and bill of materials: we call it “conceptioneering”, which condensates concept and detailed design in a single workshops and few days or weeks of work. Many pharma clients are already working with our Exyte-HakoBio layout tool. I let you imagine the collaborative power of this new tool!

We differentiate between “scale-up” and “scale-out” approaches to cope with an increased demand of a given product. A scale-out consists of the replication of a series of similar modular production units to obtain a multiple of the production capacity, as opposed to the classical scale-up consisting of the addition of progressively larger equipment with bigger capacity. A modular manufacturing platform – for example, the Miltenyi Prodigy CliniMACS – can be easily scaled-out by adding more pieces of equipment of the same type and capacity. This technique is particularly suitable for the ATMP or personalised medicine, where an expandable array of semi-automated cell culture devices can be installed side by side in a ballroom to minimise both the facility footprint (lower Capex) and the production staff (less Opex). A modular cleanroom capable of seamless expansion as a ballroom represents the optimal solution for a fast scaleout of a production area. If the scalability is integrated into the design, one can expand it with minimal impact on the ongoing production. The Shanghai Cell Factory constitutes a good example of a scalable ballroom for C>– and anyone can book a visit there, either through Miltenyi Biotec China or Exyte China!

Modularisation benefits mainly high added value products, where every month of additional revenues weights in the investment financials. As an example, we have executed in the recent past modular projects for mRNA vaccines, Viral Vectors, mAbs (monoclonal antibodies) and cell therapies.

More in general, the CapEx projects that benefit most from a modular execution are the fast-track ones. When time is of the essence, a modular, off-site prefabrication of the plant in parallel with the civil works onsite can offer the shortest, safest schedule.

Even when the schedule of the project – the so called critical path – is not driven by the building and cleanrooms, for instance in the case of sterile fill & finish units with long lead times for the aseptic filling lines, a modular execution can be beneficial if the onsite construction workforce is limited either in skills or in quantity. In these cases, the offsite prefabrication of modules mitigates the risks and improves the productivity and efficiency.

The main hubs for the fabrication of pharma modular plants are in Europe (Germany, Ireland, Italy, Sweden and others), Singapore, Shanghai and the US. But the type of modules in the market is extremely differentiated. Large room modules are predominantly built in one single hub and shipped globally. The smaller modules and pods embrace a more distributed approach, with many smaller regional workshops. Exyte opted for the latter, with several ExyCell manufacturing workshops in Asia, Europe and the US. The proximity of the module prefabrication to the construction site helps to reduce the transportation costs and meet conformity to local codes and regulations. Our workshops are in Shanghai to serve the APAC, Italy for the European customers and North Carolina for the USA market. We plan moreover to open additional ExyCell manufacturing workshops in Singapore and Ireland

A hybrid modular facility combines the offsite prefabrication of high-tech parts such as the cleanrooms, HVAC equipment, clean utilities distribution and automation systems with local, stick-built construction of the traditional building components. Concrete, steel structures, flooring and walls, steam boilers or softeners can be found almost anywhere at the right price and quality. A smarter engineering approach to the modular construction is then to “keep cheap parts cheap”: there is no advantage to prefabricate remotely elements that can be built on site, with the same quality and fast construction times. We decided to design the ExyCell with this hybrid approach, realising onsite the external “box” and the technical utilities. We don’t intend to add costs and complications where there is no advantage for the client! We aim also at reducing the transportation cost and the logistic complexity: we don’t transport “air”, as it is the case with the large room modules mostly consisting of empty rooms.

On the other hand, a hybrid modular solution works only in countries where we find the right construction trades. In the case of less developed countries, where industrial construction trades are not easy to find, we privilege the “all-in-one” room modules with complete off-site prefabrication.

In the recent past the concept of portable biolabs obeyed mostly to security purposes, for instance to respond to a biological warfare threat. Nowadays we see a renovated interest for biopharma manufacturing facilities that can be deployed quickly anywhere, let’s say in the order of few weeks, to fight pandemic outbreaks at their early onset. The new generation of mRNA vaccines are an important enabler for this development: they can be produced rather quickly, in millions of doses, with smaller equipment. But rather than a true portable plant we see a trend towards compact, dismountable autonomous clean rooms and equipment that can be transported, assembled and qualified on site, with footprints the range of 100 m². Some pharmaceutical manufacturing companies are already offering this solution with containerised mRNA production plants. The idea is to integrate a) the process know-how, b) the modularised cleanroom system, and c) the process and support equipment. In our recent experience the most innovative vaccine developers are the best promoters of this new portable concept.

On the other side, the biggest challenge to this kind of facilities is still the approval process by the local authorities, both for the drug approval and for the authorisation of the manufacturing facility. This limits the usage of portable manufacturing facilities to the emergency situations – and it will stay so in the foreseeable future.

A prefabricated modular pharma facility is eventually inspected by the same authorities, using the same acceptance criteria of any other pharmaceutical facility. The inspectors expect to see the same quality of the finishes, of process and process support, of building monitoring and control and of the air treatment systems. The challenge, therefore, is to be at least on par with traditional stick-built premises in terms of quality, reliability, product and personnel protection.

The biggest challenges in our experience are a) the design of a GMP compliant module, that is a structure built in pieces that once assembled ensures the same performances of a traditional facility, b) the risks during the transportation, both for mechanical or water damages and for the potential contamination by molds, fungi or other pests.

We at Exyte leveraged our modular experience to mitigate these risks with clever design choices. As an example, the pharma walls of the ExyCells are either sourced locally or transported separately in bulk with sturdy water-proof protections. This simple solution prevents water damage and any related mold or fungi contamination – a serious threat to the business continuity.

At Exyte, we strongly believe in the power of innovation: “bring the future of technology to life” is our motto. We strive to combine this passion for innovation with a reliable, predictable delivery of our projects.