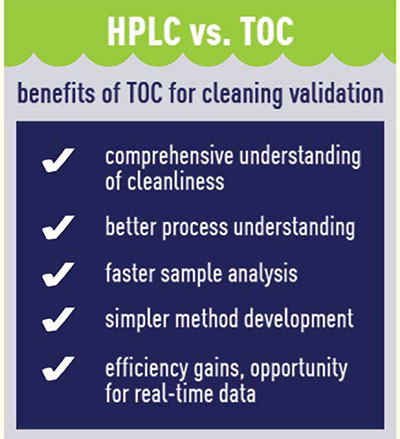

Analytical methods for cleaning validation can be broadly classified into two categories: specific and non-specific methods.

Specific Methods: Analytical methods that provide information about (or quantitate) only a specific ingredient in the formulation, commonly the active pharmaceutical ingredient (API).

Non-Specific Methods: Analytical methods that provide information about (or quantitate) the entire formulation.

API is a very small part of the entire formulation and doesn’t necessarily equate to the most toxic or hardest to clean. Thus, measuring something that is only 1/10th or 1/15th of total ingredient present inside the production equipment is a big risk. Excipients and degradants can be left undetected when using a specific method.

If the active ingredient is degraded during the cleaning process, it is quite difficult to quantify the API using specific methods. For example, degradants may have different properties than the intact API and may not elute with the same profile, thus going undetected. With non-specific methods such as TOC, degradants would be detected and quantified.

First, a feasibility study is required for the compounds of interest to determine appropriate recovery using TOC analysis. This is to ensure that TOC is suitable for performing cleaning validation with these compounds of interest. Next, TOC should be qualified as a method per USP <1225> or ICH Q2(R1) quantitative method validation guidelines. Finally, product limits should be converted to TOC limits and the recovery factor should be considered. SUEZ offers numerous resources to ensure successful implementation of these steps.

Method development is straightforward with Sievers TOC Analyzers. Acid and oxidiser flow rates need to be determined depending on the sample concentration. If concentrations are unknown, there is no need to worry – the Sievers Autoreagent feature is designed to use the correct acid and oxidiser flow rates based on sample matrix. This adds a few additional minutes to the process but is still faster than conventional specific methods.

Nothing changes for determining worst-case compounds and performing MAC calculations. The only additional step is multiplying the final limit by the % carbon of the worst-case compound to obtain a TOC acceptance criteria.

SUEZ Applications Specialists are experienced in guiding customers in successful transitions from HPLC to TOC for cleaning validation. Support may include help with TOC limit calculations and optimising protocols for soluble and insoluble API.

Using TOC requires an aqueous sample solution. That being said, many compounds that are considered hard to solubilise or even insoluble can be detected by TOC with suitable method development. Introducing heat, agitation, or adjusting the pH of a sample can greatly increase the solubility of a compound so that it can be readily detected using TOC analysis. As a part of method development, it is essential to demonstrate proper recovery of these compounds by running protocols to demonstrate linear recovery.

TOC is commonly used to detect trace residues from many detergents and cleaning agents including those with acidic, alkaline, or oxidative matrices. TOC and conductivity may also be used together to analyse cleaning agents that exhibit both a conductivity and TOC response for better understanding of both the ionic and organic cleanliness. In a study conducted in the SUEZ Applications Laboratory, CIP 100, CIP 200, alkaline and neutral detergents, sterilant sporicidal agents, and quaternary ammonium cleaners were analysed using Sievers TOC Analysers. These all exhibited linear recoveries using several concentrations, establishing the suitability of TOC for detecting residual cleaning agents and detergents.

It depends on how the analysis is being performed. Traditional grab sampling and laboratory analyses can be time consuming and take days to release equipment. At-line, wherein a portable analyser is in close proximity to the process, can reduce workflow and laboratory delays, allowing for equipment release within minutes. Online analysis with Sievers TOC, wherein an analyser is directly integrated with the process, allows for real-time data and real-time equipment release. Analysis itself takes a couple of minutes for each sample in standard mode. For processes with time constraints or in the case of profiling a cleaning process, Turbo mode can be used to gather data faster. Turbo mode gives a data point every four seconds, allowing for huge efficiency gains in a cleaning validation program.

TOC enables manufacturers to deploy Process Analytical Technology (PAT) for a cleaning validation program. Using at-line or online technology for cleaning validation greatly increases the efficiencies of a monitoring program. Not only are data and equipment released in real-time, but time spent on sampling, analysis, and human error investigations are greatly reduced using PAT applications. Furthermore, TOC can aid in optimisation of the cleaning process itself. Using TOC data, the amount of water, detergents, and time may be reduced based on process profiling capabilities of online cleaning validation deployment. Finally, as mentioned in the previous question, obtaining data every four seconds with Turbo mode can significantly aid in process optimisation.