Controlling the industrial crystallisation process poses a significant obstacle in the production of drugs and numerous other products. Digitisation of the crystallisation process now allows for radical change by increasing process automation to control overall crystallisation. The main pillars of Pharma 4.0 are process automation, improved control strategies, data visualisation, cloud edge storage, chemometrics, and mathematical modelling technologies. SmartCrys is a revolutionary integrated process control system that harnesses the mainstays of Pharma 4.0 with the combination of PAT tools in order to digitise the crystallisation process and achieve total process control.

One of the main issues faced by the pharmaceutical industry is ensuring reliable and timely access to secure, innovative, and economical medication. These issues are becoming more critical due to the world's growing but ageing population. Recent scientific developments in the healthcare market have given rise to targeted medicines that have now opened up new treatment options for individuals according to their lifestyle and genetic makeup. These developments have led to a shift within the market towards the improvement of lower dosage and extremely powerful drug products. Ultimately, these trends are contributing to additional complexity being placed within the market.

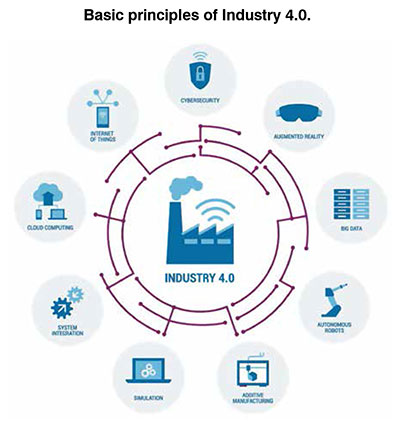

Industry 4.0 is the latest industrial revolution that seeks to address many of the problems industries are experiencing in the pursuit of enhancing the production and requirements for safer drugs. The 4th industrial revolution centres around using advanced solutions like artificial intelligence, robotics, cloud information, and storage, as well as the Internet of Things (IoT), as seen in figure 1. Digitalisation of processes by incorporating the use of data analytics and the secure storage of large amounts of data are among the highlights of the Industry 4.0. Figure1

Pharma 4.0 follows the key concepts of Industry 4.0 and aligns with basic GMP standards and regulatory constraints. Over the years, the pharmaceutical industry has adopted many industrial revolutionary changes and technologies that have improved the quality of production and led to ever more robust manufacturing. As such, Pharma 4.0 is another essential revolutionary concept that the pharmaceutical industry is beginning to embrace. Some industries are already inline with Pharma 4.0 and have applied continuous manufacturing as a novel strategy to overcome difficulties in batch processing. Many of the pharmaceutical unit operations, such as crystallisation, granulation, and tablet compression, can now be transformed by digitalisation. These innovations are achieved by utilising advanced process control strategies brought about by recent technological advancements. Crystallisation is one of the most powerful techniques used to purify active pharmaceutical ingredient (API). In recent years, many pharmaceutical companies around the globe have already moved from batch to continuous crystallisation. Digitalisation of this process is achieved through rigorous and intelligent data analytics supported by Process Analytical Technology (PAT). Implementation of Pharma 4.0 for such an important unit operation is therefore highly desirable.

Control of the crystallisation process serves as a significant barrier in the production of drugs and numerous other products. For efficient downstream operations (e.g., filtration and drying) and product effectiveness (e.g., bioavailability and tablet stability), the control of the Crystal Size Distribution (CSD) can be vitally important. Poor control of crystal shape and size can result in unacceptably long filtration and drying times, or perhaps additional processing steps, such as milling or even recrystallisation. Crystal purity and crystal shape are also crucial in determining the overall therapeutic effect of the end product. Controlling crystal shape and size can enable the optimisation of the dissolution rate, resulting in therapeutic benefits, while minimising the potential for side effects.

The essential driving force of the crystallisation process is supersaturation. Supersaturation occurs when a solution contains more dissolved material than would typically be dissolved by the solvent due to changes in the state of the solution brought about by varying its conditions. This can also be defined as the difference in the chemical potential of the supersaturated solution and the solid face of the seed crystal. The generation of supersaturation utilising different techniques is the key process technology in crystallisation. Supersaturation is usually created in crystallisers by cooling, evaporation, or by anti-solvent addition. Nucleation and growth are the processes involved in crystallisation; nucleation is the formation of clusters of solute molecules to nanometre-scale nuclei, and the growth process the increase in the size of the nuclei to micrometer-scale. Many critical quality attributes are important when considering crystallisation; for instance, CSD, crystal shape, and polymorphic form decide end-product quality—as such, controlling crystallisation to obtain these desired quality attributes is the main challenge for the pharmaceutical industry. The substantial challenges in controlling crystallisation are kinetic parameter estimation, crystal breakage, agglomeration, and poor mixing.

Crystallisation processes are complex and challenging, requiring the use of non-linear models to predict the outcome of the process. Mathematical modelling of crystallisation involves non-linear partial differential equations coupled with mass balance equations. The population density of the crystals during the nucleation and growth process is unstable due to changes in the thermodynamic and kinetic behaviour of the system. These factors impact thenumber of crystals generated, dissolved, or grown to larger sizes spatially within the crystalliser. Critical process parameters involved in crystallisation control are cooling rate, antis-olvent addition rate, impeller speed, supersaturation, seed crystal size, crystal number, along with the crystalliser design. CSD defines the final product quality of crystals, with an arrow CSD targeted for improved downstream unit operations, such as filtration and drying. Targeting larger crystals(~200μm) with a narrow CSD improves the performance of filtration, drying, and vice versa. However, new advances like sono-crystallisation, supercritical anti-solvent crystallisation are targeting smaller crystal sizes (~30μm) with a narrow CSD that eliminates the need for downstream processes such as milling, while still achieving the desired product size.

Pharma 4.0 is unimaginable without the real-time process monitoring required to advance towards the digitalisation of the crystallisation process. PAT tools are essential in assessing the real-time change in chemistry between molecules. As crystallisation is a multi-component system of solute-solvent molecules, in-situ monitoring spectroscopy techniques can be used to track the changes in chemistry between these components. Attenuated total reflection-Fourier transform infrared (ATR-FTIR) spectroscopy enables the accurate measurement of the concentration of dissolved solute in a solvent for crystallisation processes without interference from the solid crystals in the slurry. In a twocomponent system of solute-solvent, FTIR can distinguish the solute peak in total spectra, which is highly useful in tracking the supersaturation profile of the solute. This profile can be altered using control strategies and by changing process parameters to precisely control crystal size and polymorphism while maintaining visibility of polymorph solubility

Raman spectroscopy probes, simply called Raman probes, are another important PAT tool useful for monitoring the crystallisation process. Raman probes work by tracking the polymorphic changes in a solution-mediated transformation. Raman spectroscopy can show significant differences in spectra when substantial changes in polymorphism occur during the crystallisation process. One single Raman probe can also be used to detect spectroscopy for dry powder samples, as well as crystals suspended in a solvent. Unlike FTIR, Raman can detect spectral changes in both solvent and crystals within a slurry. Another revolutionary particle tracking PAT tool is Focused Beam Reflectance Measurement (FBRM). This method is used to track changes in crystal size and crystal number via chord length distribution measurement. FBRM has been a widely used technique for the past two decades as a means of understanding the crystallisation process. Real-time particle view technologies have also appeared to observe the changes in particle shape and size. These techniques are useful in observing crystal agglomeration and breakage, especially in the in-situ rotary stator milling process, where they are intended to reduce crystal size and create nucleation in-situ.

Strategies to control crystallisation

The digitalisation of the crystallisation process involves the implementation of automation control strategies as a first step in meeting one of the Pharma 4.0 objectives. Over the years, several control strategies have been implemented to control crystal size and its distribution by researchers. Their findings offer a key solution to controlling crystal size and the overall crystallisation process, leading to more robust operations and qualitative outcomes. Some of the highly valued control strategies are:

Population Balance Modelling (PBM) is the widely used method for predicting the final CSD. This requires preliminary experiments to generate the data required to estimate the parameters for nucleation and crystal growth, typically using PAT tools. This technique is also useful in predicting the final CSD of scale up studies -assuming identical conditions with laboratory experiments. PBM is the complex partial differential equation which can be solved using popular methods such as Method of Characteristics (MOC) and method of moments (MOM). There are multiple software programmes such as Dynochem, Crystal available to carry out the mechanistic modelling of the crystallisation process. These programmes use population balance models that consist of complex equations for crystal nucleation, growth, agglomeration, and breakage.

The Concentration Feedback Control (CFC) strategy is an open-loop system and an extensively reported technique used to control the final CSD. This approach produces larger crystals with uniform CSD and less agglomeration. Unless the PBM, CFC/DNC approaches are in-situ, process control strategies targeting the supersaturation are calculated directly from FTIR. CFC/DNC follows the basic principles of crystallisation to adjust crystal dissolution and nucleation via changes in temperature and anti-solvent addition. The targeted or set point value of supersaturation drives the temperature profile to match the set point values, which in turn automatically adjust the temperature to dissolve fine crystals to promote the growth of larger crystals. The DNC approach is dependent on maintaining the predetermined number of counts read from FBRM to lower the number of small-size crystals and increase the number of large-size

crystals via temperature or anti-solvent addition changes.

Model predictive control(MPC)is a closed-loop system and utilises mass and energy balance equations and PBM to predict the behaviour of the crystallisation process. The difference between actual and predicted output values is minimised via relaying feedback signals to the controller. A predefined temperature profile can be accurately controlled in MPC compared to other techniques. Data from PAT tools is highly useful for accurate prediction using the MPC approach. Non-linear model prediction control, combined with non-linear moving horizon estimation, is the most recent advancement in using an MPC approach for controlling crystallisation precisely.

Generic Model Control (GMC) was derived for the control of any batch reactor. This model is dependent on PI controllers to control process parameters and for predicting the temperature profile in the crystallisation process. This approach takes a long time to reach set point values compared to MPC.

The future of the pharmaceutical industry is set to change with the advanced technologies brought forward by Pharma 4.0. Traditional industrial crystallisation processes present a challenge due to limited process control and impact the efficient production of drugs and other products. Digitalisation of the crystallisation process with SmartCrys is a possible solution in overcoming the challenges faced by the pharmaceutical industry to date. The combination of PAT, various approaches in control strategy, as well as cloud data storage and manufacturing intelligence will prove to be extensively useful in monitoring and controlling, and digitising the crystallisation process.