In managing Chemistry, Manufacturing and Controls documents, the larger process is involved for electronic regulatory submissions to health authorities. This is a case of an entire process standard providing significant gains in efficiency. A solution is needed for this area of the biopharmaceutical industry.

Within a Regulatory department, there are Information Management needs, particularly related to the electronic Common Technical Document (eCTD) submission process. There are a number of methods for adding efficiencies to the submission process, particularly through automation and standards.

From TheFreeDictionary the definition of ‘Efficient’ is ‘Acting or producing effectively with a minimum of waste, expense, or unnecessary effort.’ However, to actually become efficient, we should look at areas that are not efficient and change them. From the same source, the definition of ‘Inefficient’ is ‘wasteful of time, energy, or materials’ So we should be looking for processes that involve lots of time, lots of energy, and / or lots of materials.

For example, consider the overall process of a sponsor producing an eCTD submission and within it the specific process of transferring Chemistry, Manufacturing and Controls (CMC) documents from a manufacturer to the sponsor. Keeping in mind the overall eCTD process, consider the specific CMC process to illustrate where and how inefficiencies can be changed. The high-level process involves:

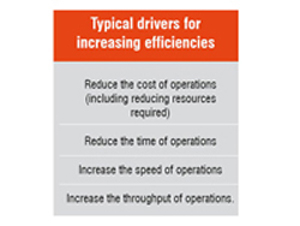

Using the specific CMC documents, how might a manufacturer and sponsor ‘reduce the cost of operations’, ‘reduce the time of operations’ ‘increase the speed of operations’, and ‘increase the throughput of operations’? When attempting to add efficiencies, the organisations should also consider the affect of changing one of these items on the others.

A sponsor might reduce the cost of operations by choosing a cheaper transportation method—maybe choosing regular mail over a specialised courier. This might increase the time of operations, however. Since both the manufacturer and the sponsor use a lot of paper in this process, maybe they could use cheaper paper. This might, however, impact the scanning step as more pages jam and need to be reproduced. A quick conclusion can be made that although reducing cost might be a driver for efficiencies, simply looking at this aspect can have expensive side effects.

Aside from cost, what other places can a sponsor realize efficiencies by addressing specific inefficiencies? There are two important methods of reducing efficiencies to address: Automation and Standards. These two can be implemented independently. However true efficient systems require both. The following discussion will illustrate this dependency.

This is automation, although not really very efficient. It could also be quite expensive. To look at what is meant by ‘Standards’, consider the same process of getting CMC documents to a sponsor. A couple of standards needed would include standard size paper for each page and a standard fax machine that sends a standard message over a telephone line. Note that if there isn’t a standard size to paper pages, all the automation aspects discussed above could be in trouble. The printer would need many sizes of paper to print on, the conveyer belt would need to adjust for different page sizes, the fax machine would need to read and send pages of different size, and the scanner would need to handle different size pages as well.

So, in this case, automation must use standards to be efficient. What about standards depending upon automation? A quick look at the above example with a manufacturer in Europe and the sponsor in the US should help. There are now two standards for paper size—A4 and US Letter. If each side keeps with their standard, will this process operate efficiently?

The conveyer belts, set to the ‘local’ standard, may not work well, since the sponsor will receive the CMC documents in A4 page size and its conveyer and scanner are set for US Letter. Since the paper sizes are close to being the same, the systems might work ‘okay’, but may not be really efficient.

To conclude this, it is important to understand that standards covering an entire process can lead to more efficiencies than any number of point-solution automation or standard steps within a process. For submissions to health agencies, the single best example of this fact is the Common Technical Document (CTD). This standard took more than a decade to put into place; however the efficiencies that can be gained from this one standard are immense in this global world of biopharmaceuticals. Without it every health agency could have different layouts of a submission and be very difficult to automate. Without this standard, submitting globally might not be a practical possibility. Even with regional differences, the CTD is a key step towards efficient submission processing.

Using PDF documents. If this standard did not exist, a sponsor might have to work with MS Word, WordPerfect, HTML, as well as PDF documents. A sponsor might use TIFF formats for images and Excel spreadsheets for graphs. Data (in the US) might come in comma-delimited files, comma-and-quotes-delimited files, Excel files, or even scanned image files. Those of you who lived through the Computer Aided New Drug Application (CANDA) era should attest to the problems of a lack of such a document standard. Only through the use of a standard format for submission documents can a sponsor add automation to its processes and gain efficiencies. These efficiencies apply to the production of a submission as well as to the review of a submission.

In addition to the CTD standard, and the efficiencies we are now gaining through use of this standard, is the electronic CTD (eCTD) standard. As the industry moves forward into the electronic submission paradigm, the eCTD standard needs to be understood as a means for providing additional efficiencies.

Within the eCTD, how else might a sponsor increase efficiencies in the CMC documents example process? If a sponsor looks at what tasks take a lot of time, it might find that the scanning step takes a lot of time. It is also very repetitive. If a sponsor uses an inexpensive scanner, a person might have to take each page, place it on the scanner, scan the documents, then remove the page from the scanner. This is both very repetitive and time consuming. The sponsor could spend some money and purchase a multi-document scanner with an automatic loader. This would both increase the speed of scanning one document and increase the throughput of the process. Note the importance of a standard page size.

To take this example a step further, even with standards and automation for this transfer of a CMC documents, it is still inefficient. Another method of gaining efficiencies is needed. A sponsor needs to increase or, in this case, change the scope of operations. So long as the sponsor is tied to the step of producing paper, it will only be able to speed up the print – transfer – scan process. The sponsor might get a one or two times increase in speed for each task automated and/or standardized. To really increase efficiency in this process a sponsor needs to change the scope of the process. This might be done by using, instead of paper, the electronic form of the documents.

If the manufacturer takes the original word processor documents and sends it electronically to the sponsor, both can increase efficiency many-fold. They do have to completely change the tasks and equipment in the process. They can forget the printing, paper transfer, and scanning tasks altogether. They can forget the printer, the fax machine, the conveyer belts, and the scanner. They will, however, need other items not used before, like a CD Writer, or email, or an FTP server. Changing the scope of an operation can have far reaching impacts on the tasks and equipment required to complete the changed operation. This might save time and money on one hand, but incur costs on the other. If the efficiencies gained are significant, the shift in costs can be justified. Organisations should consider this trade off and ‘take the plunge’ when significant efficiencies can be gained.

By changing the scope of the process and removing the paper steps, both manufacturer and sponsor can gain significant efficiencies in speed, throughput and time of operations. They will incur transition costs to make this move, however the costs of paper, people to support the printing and paper delivery, and especially the costs of scanning should be much less than the cost of a secure email system to send the documents electronically.

When sending CMC documents from a manufacturer to a sponsor, there are a number of information items very useful to the process. In Electronic Document Management (EDM) systems, this information is usually held as ‘properties’ or ‘attributes’ of the documents. A more general term for these information items is ‘metadata’. This information, this metadata, provides the means to categorize and organize documents into hierarchic structures, similar to the folder structures on a computer drive. It also provides the means to search and retrieve the documents, and to process the documents through a set of tasks. More to the point of this article, this metadata is the means through which we can automate processing of documents for the purposes of electronic submissions.

The metadata in EDM systems is also a place, sometimes unrecognized, where significant inefficiencies exist. To return to the example CMC documents process, when electronic documents are sent from the manufacturer to the sponsor, the metadata about the documents is usually not passed along. This might be because one or both organizations do not use an EDM system. These days it is more likely that both have EDM systems and so another issue is at stake. Consider the earlier problem of the manufacturer printing the CMC documents to paper, sending the paper CMC documents, and then the sponsor scanning in the paper CMC documents. Compare this to the situation with the metadata associated with the CMC documents. The manufacturer creates the CMC documents and enters metadata about the CMC documents into its EDM system. Next the manufacturer exports the CMC documents (without the metadata) and sends it to the sponsor. Finally the sponsor receives the CMC documents, imports the documents into its EDM system and enters metadata about the CMC documents. Here is a case of an inefficient process.

How could these organisations address this inefficiency? By automating the process? If it were simply a matter of automation, this probably would have already been done. The problem with attempting to automate the process is that there are no standards through which automation can be efficient. In particular, there are no standards for the metadata in the different EDM systems. This is similar to the problem of not having standard page sizes for the printer, conveyer belts, and scanner discussed previously. The problem is brought back to the inter-dependency of automation and standards.

A standard for EDM metadata is needed in order to address this inefficiency and allow for automation to be efficient. Without such a standard attempts to automate EDM processes, especially between EDM systems as with the manufacturer and sponsor, will not be efficient – not be cost effective, from the standpoint of the trade off mentioned earlier. In the case of the CMC documents example, the larger process involved is for electronic regulatory submissions to health authorities. This is a case of an entire process standard providing significant gains in efficiency. A solution is needed for this area of the biopharmaceutical industry.

The topic of the eCTD standard was raised earlier in this article and now enters again. For documents held in an EDM system and used in an electronic submission, the eCTD standard provides a basis for defining standard metadata to be used in the EDM system. Through use of such an EDM metadata standard, automation can be applied to such processes as sending a CMC documents from a manufacturer to a sponsor, transferring documents between EDM and publishing systems, even for submission review systems—especially if the submission is held in an EDM system. Being an entire process standard, there will be many places efficiencies can be gained with an appropriate standard.

A final word about the title of this article: A ‘Standard’ is really information about how to generate some object, be it paper size, character fonts, nuts and bolts, or an eCTD submission. It is this information aspect of a standard, in the Regulatory Submissions arena, that requires Regulatory Information Management.